TCA Launches New Research Slabs to Advance Concrete Durability - July 2025

As part of our ongoing commitment to advancing concrete knowledge and best practices, the Tennessee Concrete Association recently completed the placement of two research slabs at our Nashville campus. These slabs will allow us to study real-world durability factors—such as curing, finishing, and deicer exposure—over time.

This project will not only inform our own members but also support national efforts in collaboration with the American Society of Concrete Contractors (ASCC). We’re proud to be working closely with ASSC on this initiative. ASCC plans to replicate similar studies across the country, and TCA will share our findings to support national learning and industry-wide advancement. One such project is already underway in Iowa, thanks to the leadership of Hahn Ready Mix.

The main slab placements occurred on July 15 and 16, with additional pours on July 17 supported by Grant Johnson of Baker Concrete Construction. These slabs will give us valuable insight into how different mixes and surface treatments hold up over time—especially in Tennessee's unique climate and exposure conditions.

Thanks to the following member companies and partners who donated materials and services:

-

Baker Concrete Construction

-

Mobile Materials Nashville

-

Midstate Mobile Concrete

-

PRI of Tennessee

-

Clemmons Concrete Coatings

-

Euclid Chemical

Prep work for the slabs was completed by TCA staff, led by Joseph McDaniel and Grant Johnson with Baker Concrete Construction. Both slabs were sized to take approximately one full load of concrete. Both slabs were divided up into different areas to represent different finishing procedures, curing, and sealing with a goal of capturing the most common conditions for concrete placement, finishing and curing that occur in Tennessee.

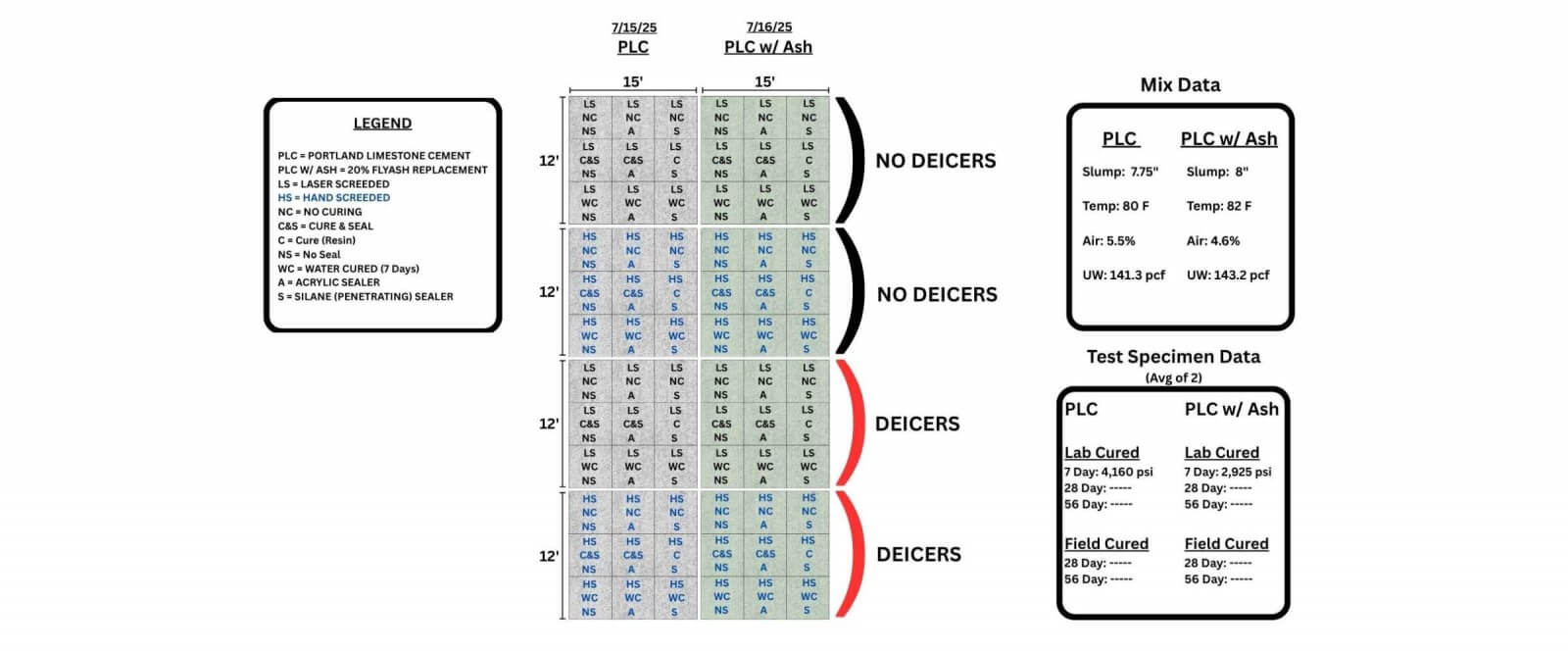

The result is 72 different slabs each approximately 4' x 5'. Each day concrete placement required a full load of concrete and resulted in 36 different test panels. The Mix on day one was a straight cement mix, which today in Tennessee means that the cement used was a Type 1L cement. The slab for day two was a similar mix with a 20% class F fly ash replacement.

Finishing for both slabs was conducted in the same manner, under the supervision of Grant Johnson. Half of each day’s pour was screeded using a vibratory strike off tool and the other half was hand screeded with an aluminum strike off board. All concrete was then bull floated, edged and broom finished. The slabs were then sawcut to clearly delineate the various panels and conditions that we want to observe. These conditions are represented in the schematic drawing that contains a legend to describe the conditions of each of the 72 test panels that were created as a part of this research.

Half of the test panels will be subject to deicer application late in 2025 and early 2026, and in subsequent winters. This will allow us to observe the impact of deicer on all of the various curing and finishing conditions that we have created.

We’ll continue monitoring the test panels and will share annual updates on surface conditions and durability—especially after deicer application this winter. Stay tuned for future insights as we continue this multi-year research effort.